Technology

At the core of our offering and competence, are our unique sensors. In addition, we offer pre-studies, all hardware, electronics and software required to integrate to the customers’ control system, installation, start-up and service of the full gas measurement and control system.

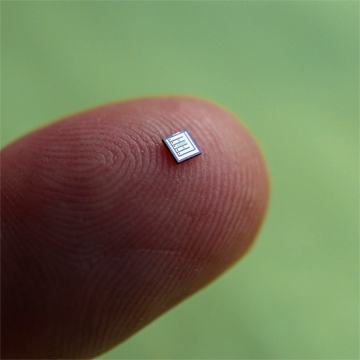

The SenSiC’s gas sensor technology has been developed over 20 years of research at Linköping University (LiU) in Sweden and is based on the use of Silicon Carbide (SiC) technology for semiconductors and long-term experience with combustion processes. This technology has just recently become viable for the commercial production of high volume, price competitive products.

Unlike existing sensors on the market, the SenSiC sensors offer full functionality in very high temperatures and harsh environments and withstand thermal shocks. Because the sensor semiconductor chip is placed directly in the exhaust gases (in situ), there is no extra cooling delay as with other sensors, and therefore, the response is quick. A single sensor unit can detect multiple gases.

The external control unit is fully software controlled and offers industrial interfaces for programmable logic controllers, as well as low cost integration within existing control electronics for domestic biofuel heaters. SenSiC also provides the sensor control software for customer-produced control electronics.