About Us

SenSiC AB develops and produces gas sensors which are the core in the systems we offer. Typical applications are found in the control of combustion in industrial processes, such as gas burner control in steel mill reheating furnaces. Other applications are under development, see further under the tab Our offering.

Improvement in combustion efficiency and emission reduction results from the sensors ability to measure oxygen (O2), carbon monoxide (CO) and ammonia (NH3). The sensor Control Unit offers remote control and supervision, as well as automated calibration.

Our vision is to contribute to a cleaner environment.

SenSiC AB was founded in 2007 as a spin-out from Linköping University (LiU). SenSic AB is located in Kista and Linköping. Ever since the start, SenSiC AB has always had a strong connection to Linköping University in research.

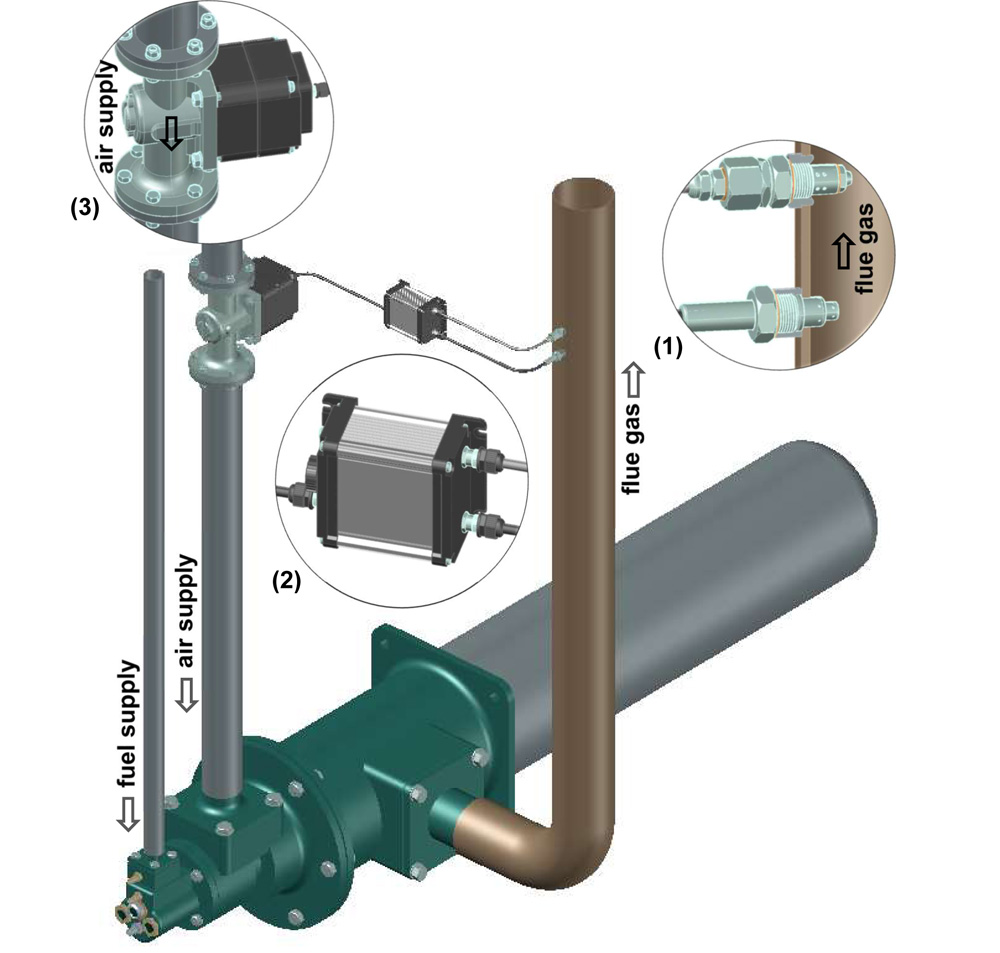

(1) CO (a) and O2 (b) sensor mounted directly to the flue gas channel

(2) Embedded sensor driver-, sensor data acquisition, signal processing-, and mass air flow control electronics/software

(3) Mass air flow control valve